You may download related documents about the product for detailed information.

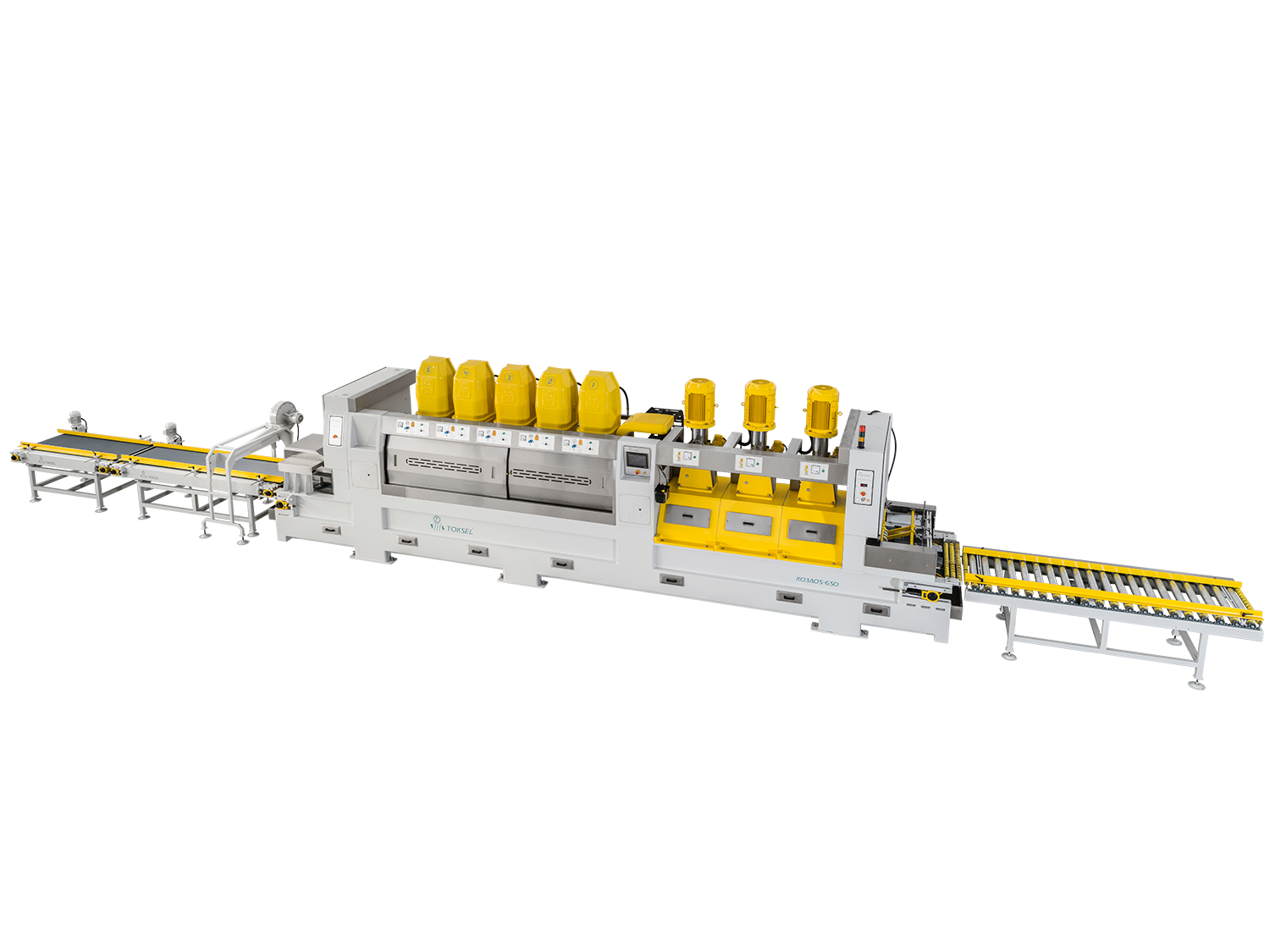

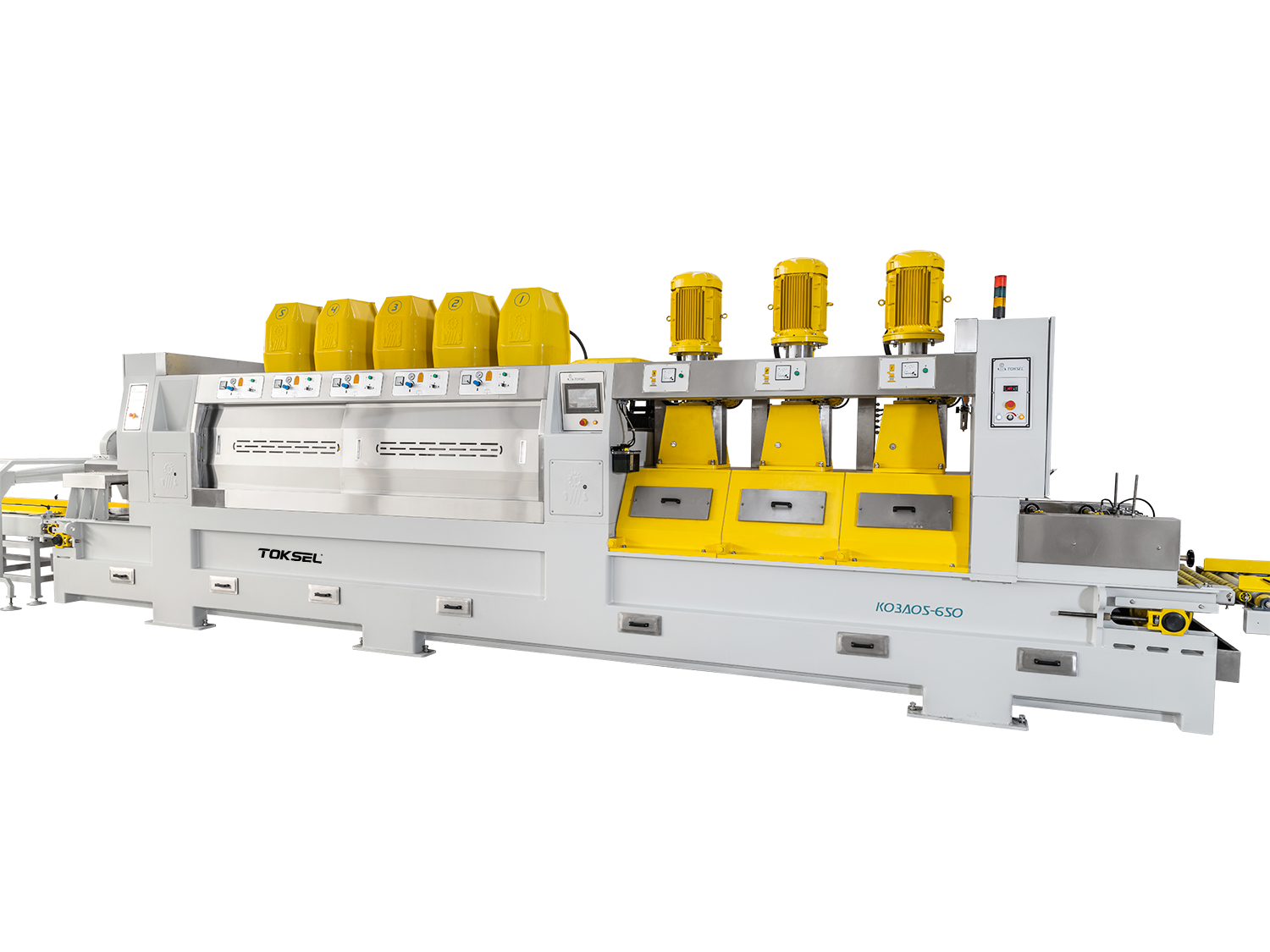

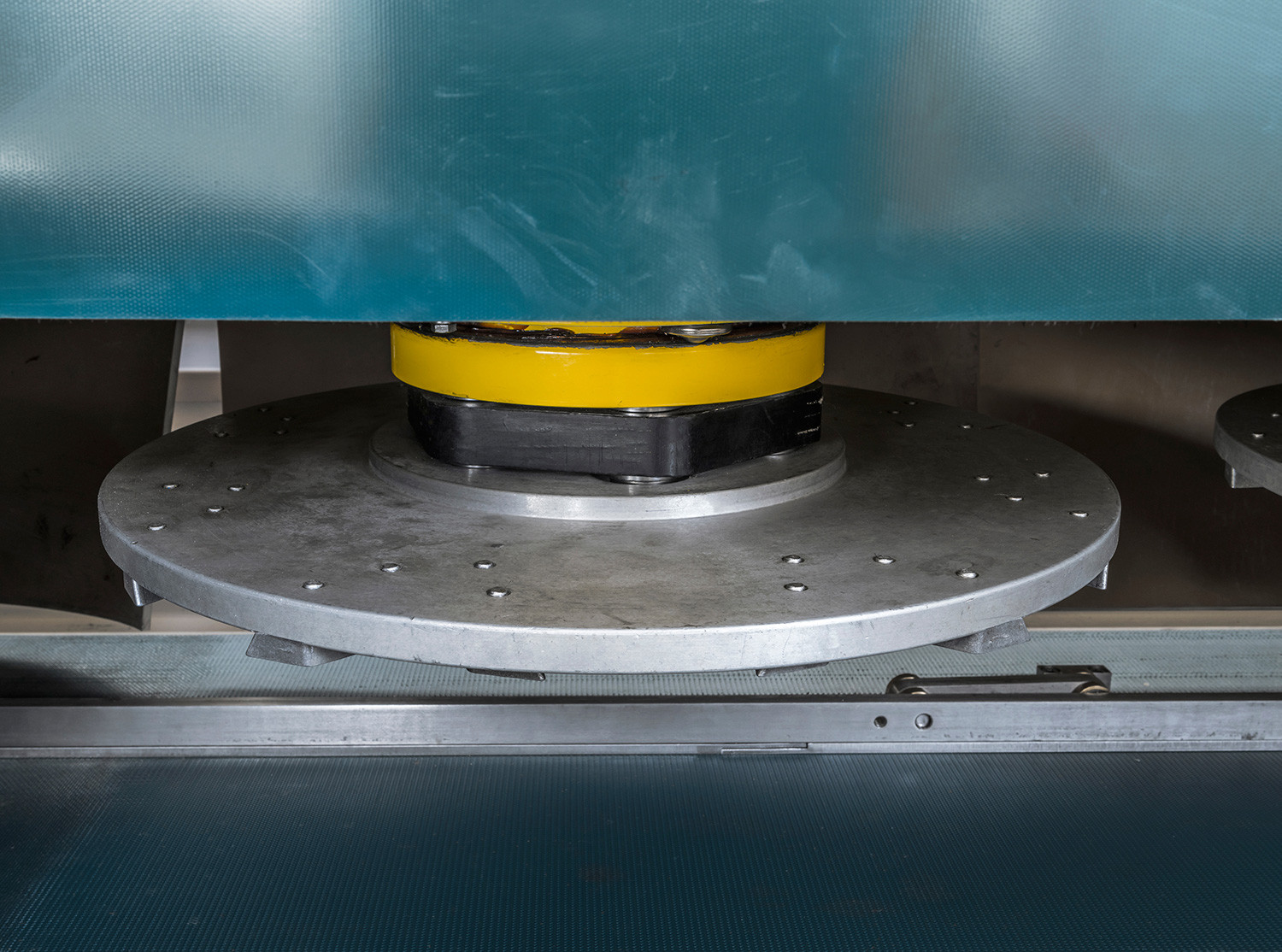

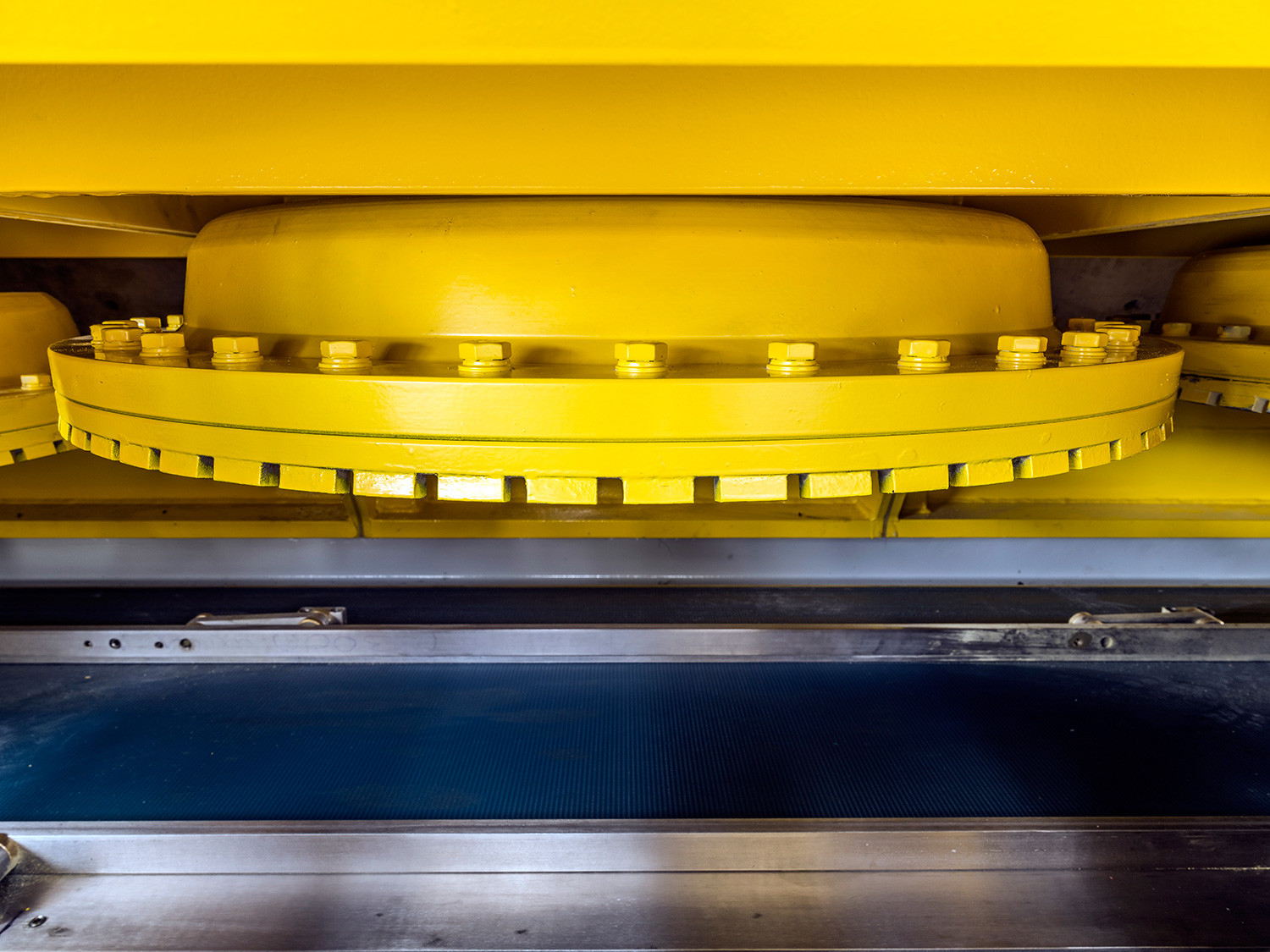

Pegasus ® Caliber Polishing Machine

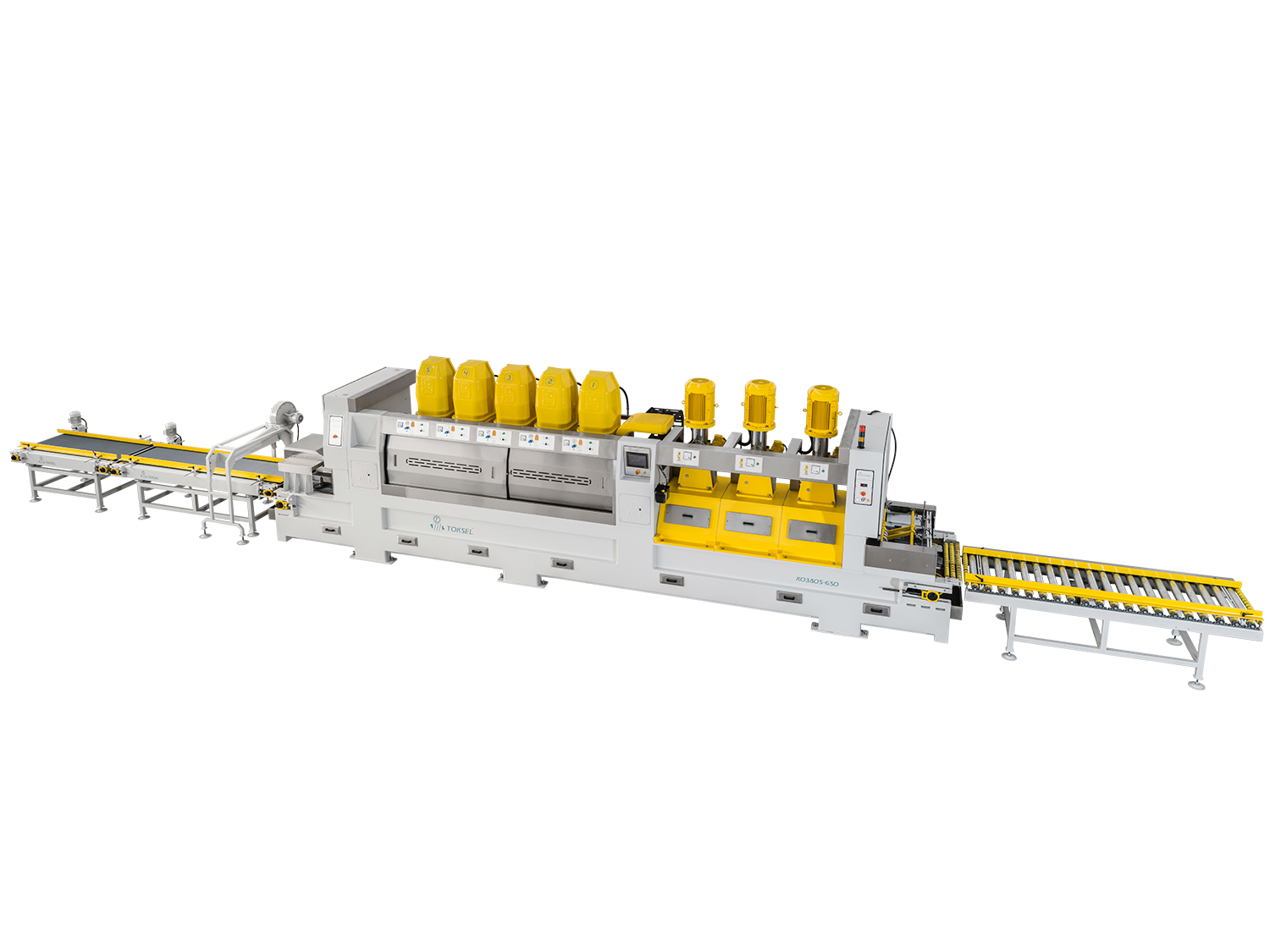

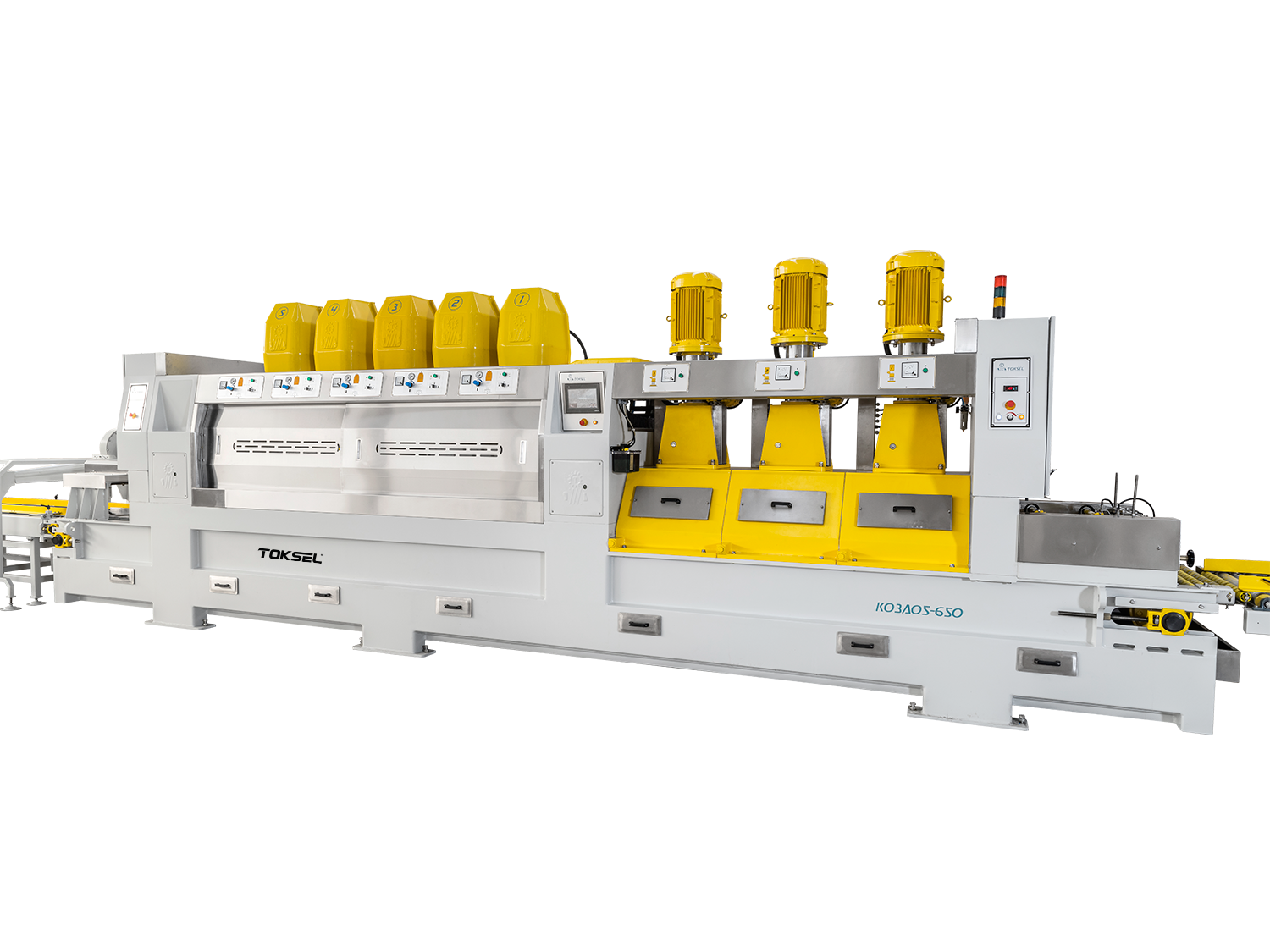

Pegasus ® caliber polishing machine is a full automatic and PCL controlled; puts semi-finished products such as marble, travertine etc. through calibration and polishing process. Pegasus ® not only provides service with standart rack designs for 46cm. and 65cm. stone sizes but also does it with special designs for marginal measurements to its users.

Remote Tracking and Intervention System

Pegasus ® has remote tracking and intervention system. If desired, Pegasus ® is able to give all kind of information and data about machines’ production statements, stoppage times-causes, process condition of a stone, its instantaneous bridge and production speed and current processed product through any device has connection to internet.

In calls that will be sent digitally to after sales services, users will be notified and redirected immediately.

Outstanding Features, Above Standart Quality

The collection of interventions and datum are carried out by LCD touch-operated operator screen.

Panels on the machine have traction of power and all electronic components are chosen first class quality.

Not different from Excalibur ® and Alligator ®, Pegasus ®’s friction surfaces of the band, like all other banded machines, are covered with 304 quality stainless material.

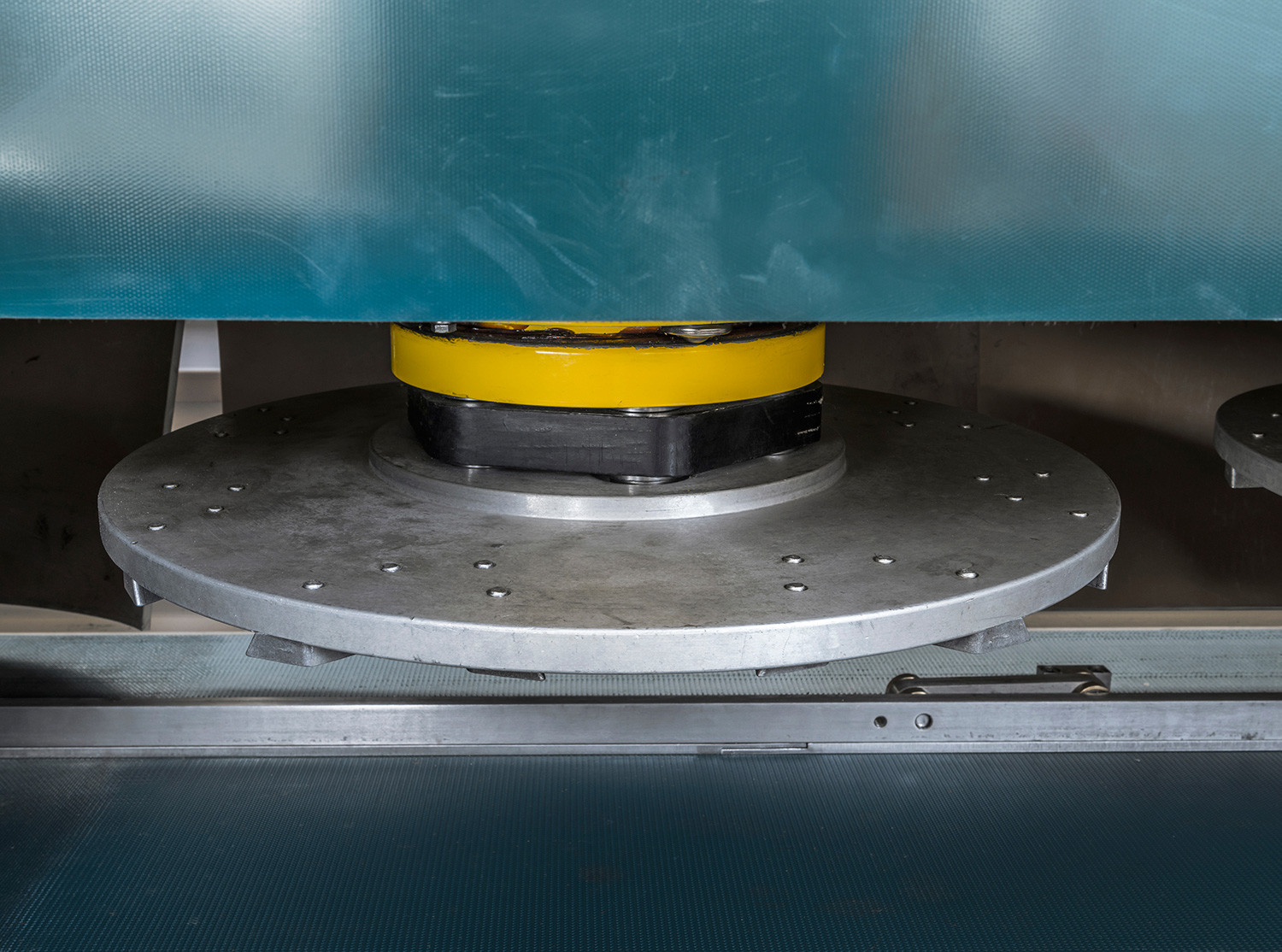

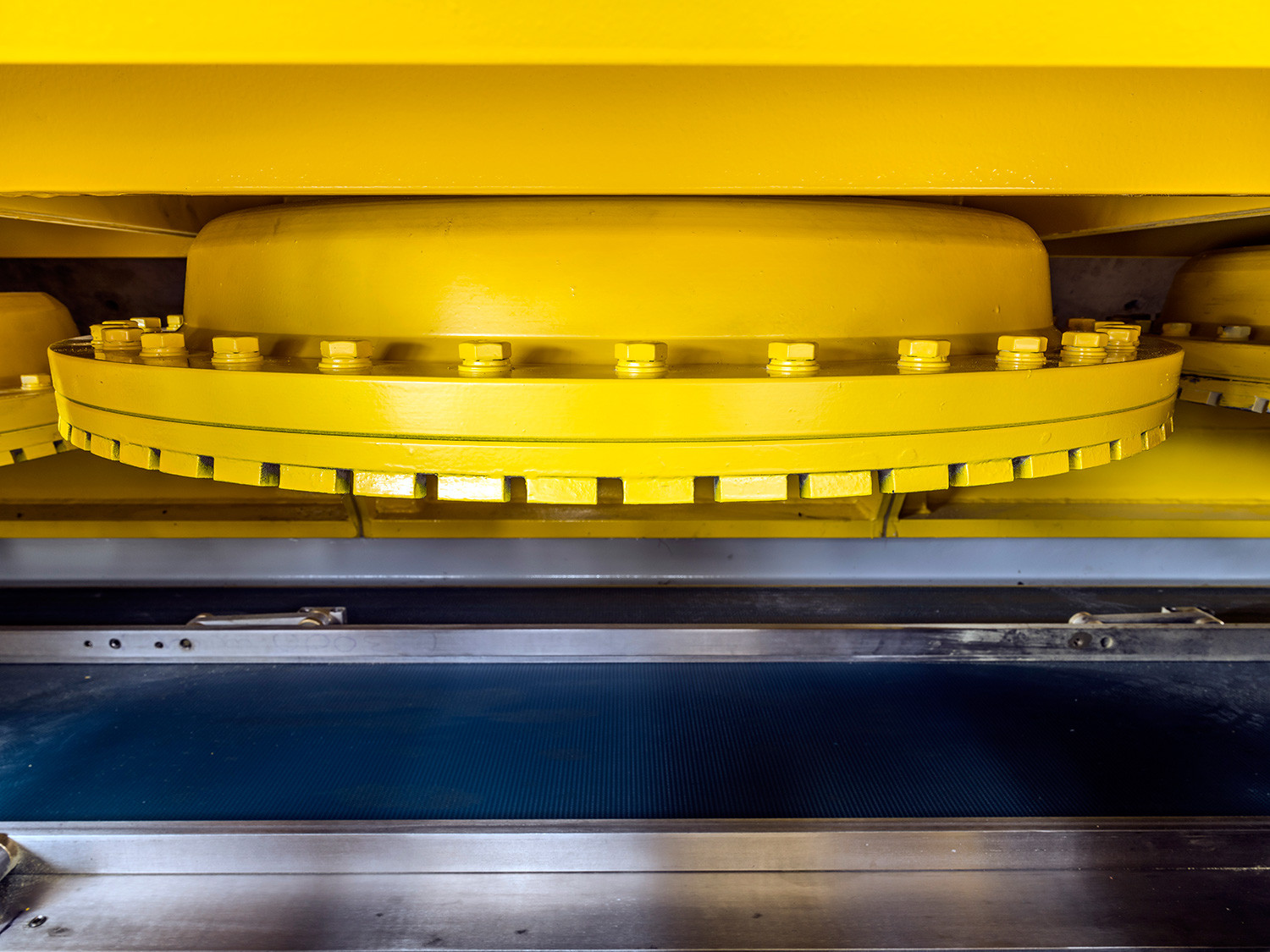

Pegasus ® caliber heads are integrated to the engine directly and Poli-V strappings are stimulated by abrasive heads. This matter lets industry to save on energy up to 30 percent.

Top End Processing Technology

Pegasus ® calibre polishing machines may have long chassis frame. In long chassis framed machines such as calibre polishing etc. one most the most important factors that determine the precision of stone process is that long surfaces are subjected to machining in one go. Toksel is the firm, in the region of İstanbul, which is able to process the longest and biggest pieces. CNC 3.5 axis rotary table automatic screw machine included in it, is able to process vertical machining centers and other CNC universal machines and long polishing machine in one sitting.

In the other caliber polishing machines whose chassis frames are processed step by step or section by section it is impossible to catch up with Pegasus ® precision.

Auto-Pilot System

Pegasus ®, with unique design and exercising, offers auto-pilot system to its users that sensors thick passes and decreases conveyor pace.

Pegasus ® can sense without any intervention and by lowering the speed to process the thich pass, executes calibration process. Thanks to this feature of Pegasus ®, layovers, casualties and mistakes are minimized.

Speed of Pegasus ® is constantly hold on the maximum speed set by administrator if all conditions are appropriate. When this feature is put into use, Pegasus ® deactivates manual speed adjusters automatically. For this reason, unnecessary slowing down of polishing speed is impossible. This feature in Pegasus ® allows stone industry to make more production with existing energy.

Automatic Calibration System

It is calibration settings that cause the most trouble to users and spend working hours in using polishing machines.

Pegasus ® has an automatic calibration setting system completely designed and practiced by Toksel. You only need to enter the desired stone thickness from the touch panel. In seconds Pegasus ®, full automatically, regulates all the calibers considering structure of rock, caliber unit number and pass quantity.

This setting is done so sensitively that it cannot be done through human capabilities. Thereby, you can get maximum efficiency from calibration process spending minimum time and effort.

Automatic Pause System

Horizontal size control, available in Pegasus ® that is adjustable according to plates’ measurements, are compeletely made of INOX 304 quality stainless material. Horizontal size control (automatic pause system) is a fully automatic system, the motor is mobile and width values can be seen from the touch screen. After setting value on the screen for width of the stone to be processed, automatic pause system steps in and opens metal sheets as desired.