For detailed information about the product, you can download the relevant documents.

Pegasus ® Slab Polishing Machines Lines

Pegasus ® Slab Polishing Machines, performs surface smoothing and polishing of plates. Polishing/gloss heads make circular motion on the stone surface and thanks to traveling bridge system, polishing every point of the surface to be erased at the required quality.

With the linear heavy duty bearings called MR on the market, the traveling bridge system, which carries the cross-sectional heads supported by the movement, delivers the perfect polishing quality to its users.

Cae Finite Elements Analysis

The Pegasus ® chassis is made of the most rigid materials in the industry. Designed for a construction that is more durable than the granite polishing materials found in the industry, Pegasus ® offers a perfect experience for its users.

Although minimum 550 NPI main chassis profiles are used, intermediate travers are in minimum 300 NPI standards. Designed at a frequency similar to the web, chassis finite element analysis methods and engineering analysis are performed and then taken into production.

Traveling bridge, main body (chassis) and all other components carrying Pegasus ® heads are manufactured after static, dynamic analysis. This process is repeated in every revision.

Quality Expectations Breeds Technology, Technology Breeds Quality

Plate polishing machines, chassis is long and heavy because of the lack of sufficient infrastructure in cases where the part is subject to processing. Although it is not possible to achieve the excellent level of polishing quality in the polishing machines produced as a result of such processes, the Pegasus ® chassis is processed at one time on our computer controlled machines, which can handle the latest technology and materials in our machining field, which is 18 meters long. Each point in the Pegasus ® chassis has the same measurement standards as each other. This is the biggest factor that Pegasus ® has achieved excellent polishing quality.

WORLD’S HİGHEST STAİNLESS DENSİTY POLİSHİNG MACHİNE

Pegasus ® is equipped with as much stainless material as possible in water contact areas. The machine elements (cap screws, cap nut, rondel, couplings etc.) are completely stainless, the cutting fluid used in the machine is discharged to the waste water channels by means of the stainless channels. Stainless water channels are designed as a removable drawer.

The entire surface of the titanium sheet welded to the Pegasus ® chassis is designed to be disassembled with 304 grade stainless steel sheet to prevent wear in band frictions. The edges are specially preserved so that no water or mud can penetrate between the stainless plate and the platinum plate. This situation was designed to prevent the erosion of the material under the band of mud and water leaking under the band. 304 grade stainless steel is more resistant to wear than metal material.

4th Industrial Revolution In Our Sector

Pegasus ® users are able to remotely monitor, generate reports and receive reports and remotely intervene.

With camera systems installed around Pegasus ® and integrated with PLC, Pegasus ® can remotely monitor, inform users of the polished stone from across continents and inform the company managers with extra information sharing such as reasons for stopping, downtime etc.

Pegasus ® can share images, written information and warning messages to your computer, tablet, smartphones at any time.

Polishing Quality On Pegasus ® World Standards

Pegasus ® presents Polishing quality to its users on World standards. The other reasons for this would be to sort out the following;

- Voice, lighting and display emergency warning system with operator warning system is available,

- 8 pieces of Polishing brush or Polishing abrasive stone can be installed around the abrasive head disk and these passes are provided with aluminum exchangeable claws,

- Pause fish plates are stainless and adjustable,

- Fully automated and PLC controlled,

- Touch operator panel available,

- The electrical and electronic components used in Pegasus ® select from top quality products,

- The operator is warned from the LCD screen at the end of the abrasive stone,

- Central system liquid automatic lubrication system,

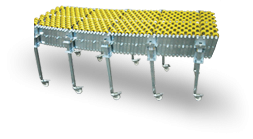

- Specially produced finger-patterned plate for Pegasus ® which tolerates stone deflection, is used in rubber band qualities,

- Abrasive Polishing heads are integrated into the engine with Poly-V belt and there is amhive bedding system,

- All head systems with high IP technology increase the resistance to impermeability,

- Head motor current monitoring ampermeters are also available in Pegasus ® According to the physical properties of the surfaces to be polished in rows of abrasive heads,

- Plate reader laser cluster system in the machine,

- Energy saving engines are used in the machine.